The previous work on our automation chamber was an awesome feat. After living the victory we had automating the chamber with Python, and KivyMD, I found another opportunity through software called LabView, by National Instruments. LabView is awesome, and fully featured software suite that allows users to program and automate all sorts of equipment using a drag and drop style editor. Now the admins at my college were looking for opportunities to use our wonderful hardware, and this where Exquadrum came into play. Exquadrum is a latin phrase for “thinking outside of the box.” They are an aerospace engineering company that builds and tests propulsion technology, for both NASA and the U.S. Defense Advanced Research Projects Agency (DARPA). They had just the opportunity for us. They challenged us to develop a testing procedure for there proprietary satellite components that would be subject to orbital conditions using the LabView software.

This meant cycling a component from temperatures of -60C to 130C for several cycles. A cycles time length is determined by the orbital height that the device will be at during its operation. In our case, it was Low Earth Orbit (LEO), which meant 45 minutes of hot, and 45 minutes of cold. The number of cycles was 10. The purpose behind this testing was to be able to visualize any electronic and/or mechanical failures that would occur under those conditions. Failures from this type of exposure happen as a result of thermal expansion and contraction. For electronic circuits, this happens primarily in the solder joints.

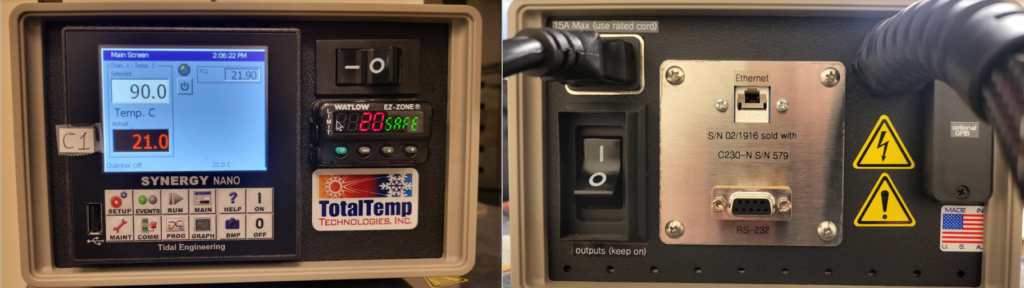

To accomplish this process, we installed LabView onto our laptops, and connected to the controller of our environmental simulation chamber. This controller, the synergy nano 2, is responsible for setting and maintaining the temperature of the chamber. We did some research and found that the controller responds to a specific command set through serial communications. The serial communications port was established over 30 years and is used to allow two computers to talk to each other. The port can be seen on the back of the controller, in the image below, labeled as “RS-232”.

Interestingly enough, LabView has a method of sending and receiving serial communications data. After many attempts, we were able to get the communication set up, and were sending commands through LabView, to the chamber. We were also able to read the chambers temperature as well! It was a delightful moment to see this level of control happening, all with the press of a button.

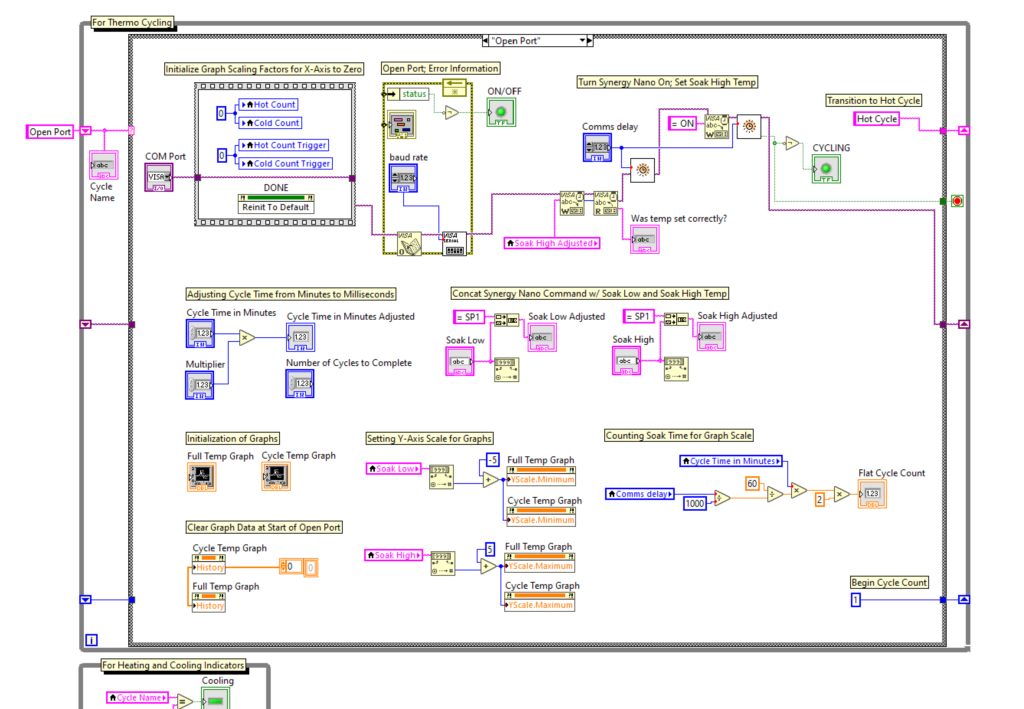

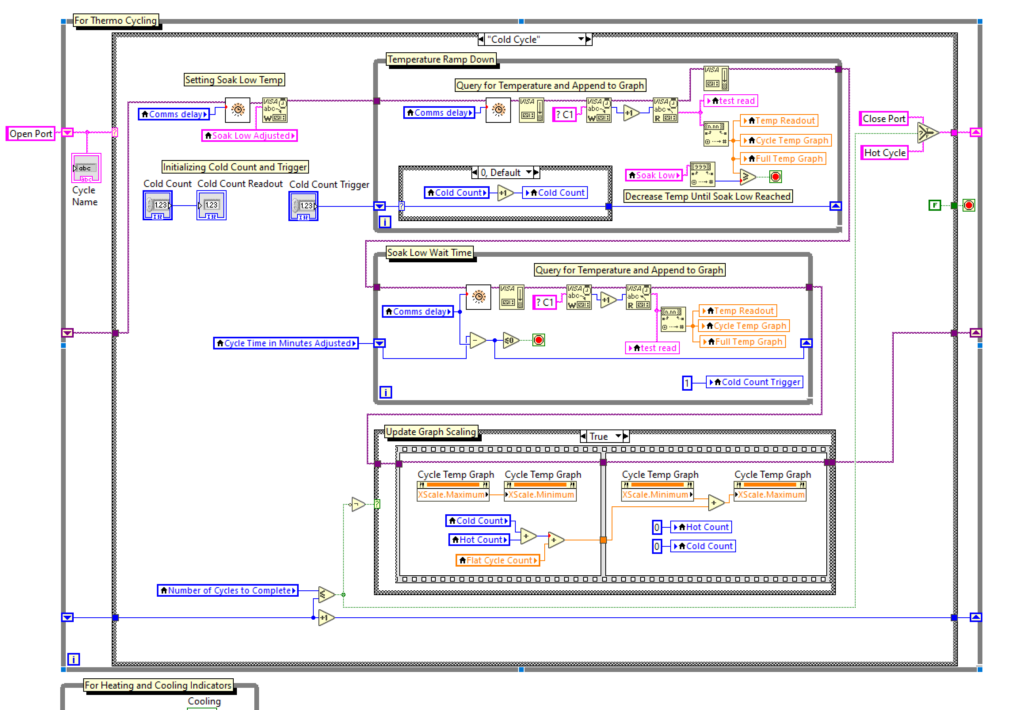

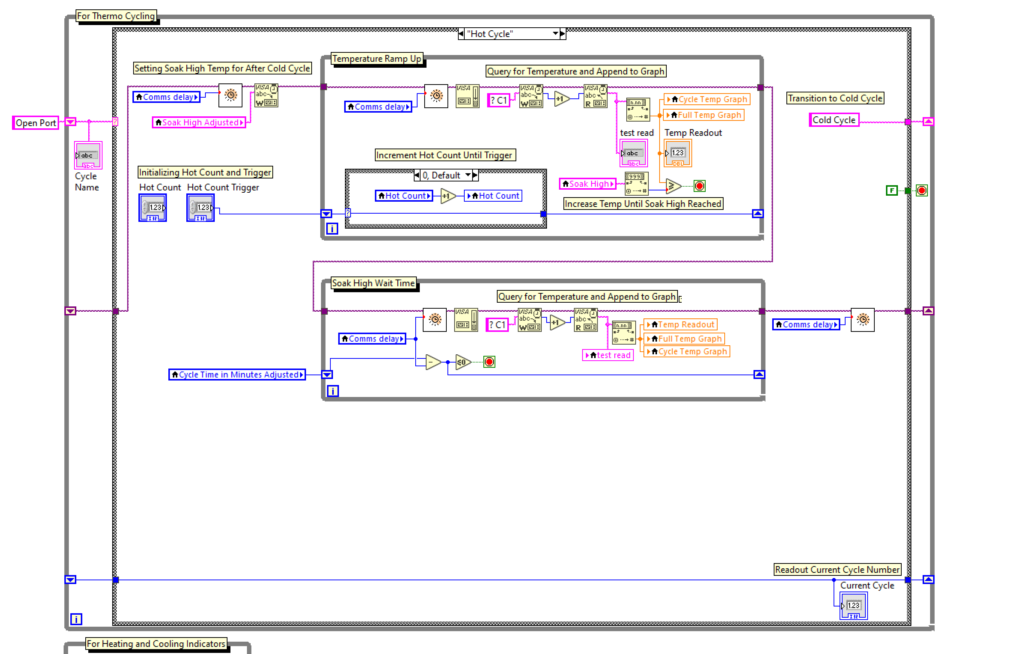

Understanding how to control the chamber was only half the battle. We had to figure out the programming equivalents for while loops, pause statements, conditional checks, and variables. Thankfully, LabView is really well documented. It even has the documentation build into itself, allowing a user to figure things out just by hovering over a certain icon. We hacked away for weeks, and came up with something that looked like this.

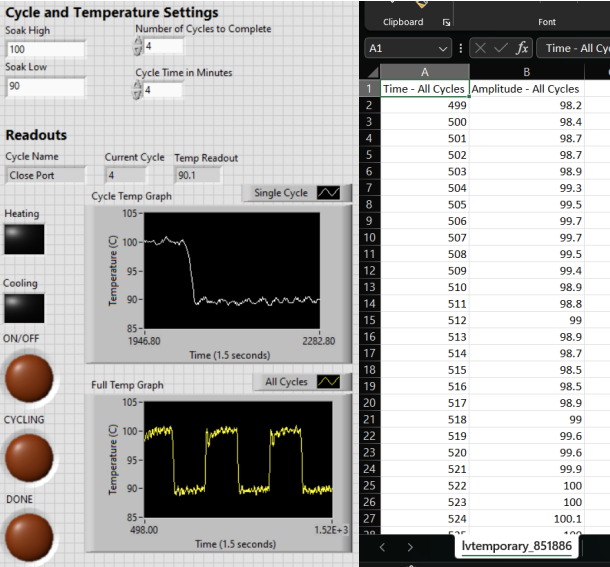

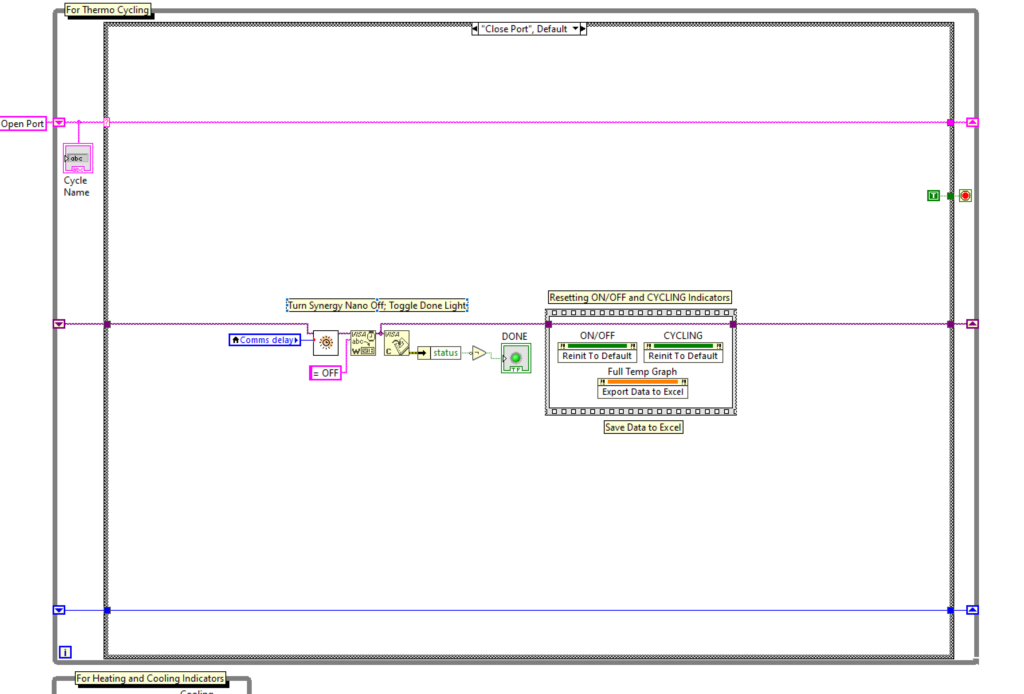

Initially the process looked scary, but it wasn’t as complicated as it looks. We divided the process into four states. Setting up the connection to the chamber, conducting a cold cycle then a hot cycle, repeating those cycles for a number of times, and then saving data/closing the connection between the computers. This can be seen below.

My team worked hard to develop this code, and we were able to fully automate the testing process. We are able to set the desired temperature ranges, the time for the cycles, as well as the number of cycles to occur. On top of that, our code data logs the temperatures of the chamber for data analysis and visualization purposes. I am proud of the team, and would like to give special thanks to our Mentor, Pr. Michael Gariety at College of the Desert who guided us and oversaw the project. The team members who worked hard to make this happen where: Alfredo Covarrubias, Derek Carmona, Luis ReyRey, Miguel Rodriguez, Monica Michael, Reza Abdoli, Yesenia Gonzalez and myself, David Jackson! If any one is interested in our Lab View VI code, we have it posted in my Git Hub repo found here 🙂

I would also like to give thanks to staff at CoD for making this happen and the folks with NSF-Crest grant foundation. Namely, Dr. Carl Farmer, Sandra Farmer, Dr. Kimberley Cousins and Matt Jackson. We are also very grateful to Elias and Eric at Exquadrum for giving us this opportunity and allowing us to visit there awesome facility. It was great to see the work they are doing in person.

Leave a Reply